Process Control: Full Automated Flow

taReo offers comprehensive features for complete automation of deposition process control.

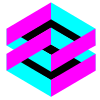

With taReo, you can effectively analyze inline measurement data scans, accurately predict termination points for layer deposition, perform inline characterization, make decisions regarding design reoptimization, and if needed, reoptimize the remaining layers on-the-fly.

Fig. 1. Implementation of taReo into a fully automated deposition process.

Monitoring concepts

taReo supports all broadband monitoring concepts: with single monitoring substrate or with multiple chips (witness glasses).

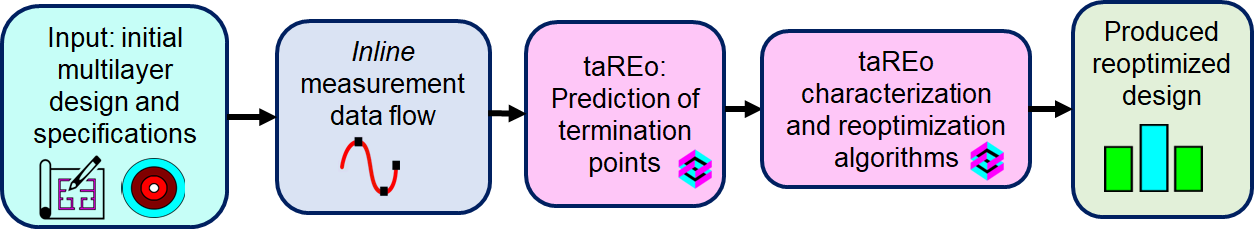

Inline measurements can be performed not on the produced sample but on a test glass or a witness chip. This test glass can be placed on different positions in the deposition chamber, and deposition rates of thin-film materials can be different. Consequently, there may be variations in layer thickness between the sample and the test glass. Some deposition plants offer the flexibility of using multiple test glasses or reusing them for monitoring purposes. Figure 2 provides a highly simplified depiction for better understanding. In some deposition plants, using of multiple test glasses or reusing of test glasses is possible.

Fig. 2. Simplified schematic of a possible monitoring concept: samples being produced are placed on the calotte; measurements are recorded on the testglass position.

Refractive indices inline and offline

taReo allows you to to consider the differences in refractive indices of layer materials between inline and offline measurements, which can arise from vacuum shifts, thermal shifts, and porosity effects.

- In general, theoretical designs are calculated based on specific environmental conditions. For instance, assumptions are made that the sample will be utilized under room temperature conditions or subjected to high temperatures as a result of interactions with laser beams.

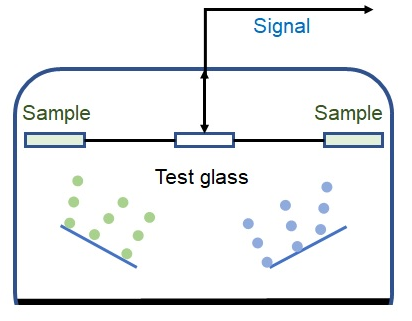

- During the deposition process, only inline spectral characteristics are available, which may differ from the spectral characteristics of theoretical designs due to several factors. These differences can arise from changes in the optical constants of the layers after exposure to the atmosphere, as well as variations in layer thickness caused by water absorption from the environment (see an illustration in Fig. 3)

- It can happen that both effects take place and, therefore, both layer thicknesses and optical constants can be different due to vacuum shift of layer materials as well as expansion of layer thicknesses.

- Moreover, there can be variations in layer thicknesses and refractive indices between inline and offline measurements, which can be attributed to thermal expansion of the layers and thermal shifts in optical constants. The deposition process often operates at elevated temperatures, often ranging from 120-400°C. This implies that inline and BBM measurements are conducted under high-temperature conditions, while measurements in the atmosphere are performed at room temperature. Consequently, due to the thermal effects, there will be differences in spectral characteristics observed between these temperature conditions.

Fig. 3. Comparison of transmittance in vacuum (red crosses) and transmittance after exposure to air, assuming a 1% expansion for high-index layers and a 2% expansion for low-index layers.

Color characteristics and integrated characteristics

In taReo, you have the flexibility to work not only with spectral characteristics such as reflectance and transmittance but also with color and integrated characteristics. This means that you can optimize the thicknesses of the remaining layers based on desired color or integrated characteristics. The width of the spectral line can be taken in account as well.

Fig. 4. Illustration: integrated spectral characteristics, for example, solar integrated values, colors, and line width are taken into account.