OTF Studio Development History (updates and bug fixes)

25.85 (30.12.2025)

1. Reverse Engineering enhancement: Models with symmetrical configurations were added: when the same unknown coating is deposited at both sides of a substrate (for example, ALD process) and subjected to the RE procedure.

2. Interface improvements in OM mode:

- Stripes and dashed lines showing the boundaries of layers can be configured independently. The top of the design is always indicated by a gray dashed line, allowing the final termination point to be seen more clearly.

- Spin buttons are now not visible at Swing cells, since these values are not editable.

- Layers with unsatisfactory monitoring conditions are now visible if no Machine object is loaded to memory.

- Report Settings tab is removed from the Results ribbon, since there are no related settings.

- New tab for Runsheets is removed from the Environment panel and from the OM Home ribbon, since monitoring runsheets can only be edited.

- Inconsistencies in displaying stripes when monitoring with multiple chips have been fixed.

- Correction of the Export to LMR option: The multi‑chip strategy warning is now issued only when different chip types are used. If the strategy contains only one chip type, the LMR export proceeds without warnings.

3. Improvement of color options:

- Cut, Copy, Paste, and Select All options were added to the right‑click menu in the Color Range target editor (AS and RE modes). The Copy/Paste functions are especially useful when importing complex range definitions from Excel.

- Axes labels and tick marks in color diagrams now update dynamically when the diagram is zoomed (in both AS and RE modes)

4. Other improvements and bug fixing:

- Export to LightTools format improved: Im(n) of materials are now exported with positive sign.

- The Tools tab is no longer shown in Angular mode, since Tools operate over wavelength ranges rather than angles.

- The caption of the Integral Specification Editor was wrong. Corrected.

- Tolerance column was visible in the Integral Specification Editor. Removed as not relevant.

- Phase unwrapping can be applied during integral values calculations.

- Export to the LMR format is added to RE mode.

25.81 (30.11.2025)

1. Angular Targets and Specifications implemented:

- Targets and specs can be formulated now in terms of incidence angle. Access to angular targets and specifications via: Target Editor → click on any cell → Mode → Angular or Specs Editor → click on any cell → Mode → Angular. With the new feature, design challenges involving angular targets and specifications can be configured much faster and more effectively. The Target Preview and Specs Preview panels display the respective targets or specifications according to the selected mode.

2. The Dark Theme is available in OTF Studio under: Settings ribbon → User Interface → Theme.

3. New features in characterization and reverse engineering modes:

- Partial Discrepancies plot can be extracted using Copy Numbers (right-click drop down list on the plot).

- The Copy Numbers feature has been implemented in the Fitting panel, enabling extraction of numerical measured, model, and discrepancy values directly in an Excel‑like format.

- If multiple measurements (different characteristics or different AOI across several subpanels) are included in the loaded measurement, integral values can be calculated and displayed for all measurements when the All Pages setting is selected in the values configuration panel.

- A new Measurements as Lines feature has been added to the fitting panels. It replaces markers with continuous curves.

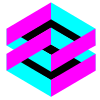

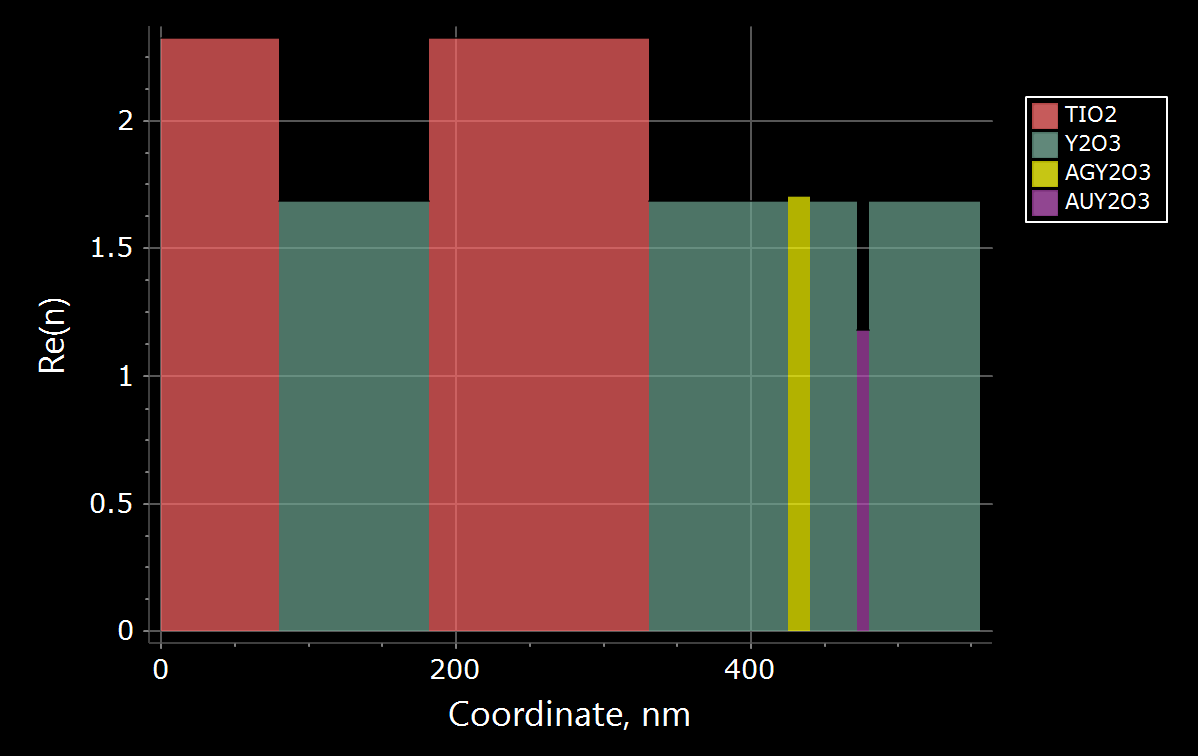

4. The new refractive index profile plot (Profile panel) represents thicknesses and refractive indices of the designs simultaneously:

4. Import/Export improvements:

- Better support of Drag & Drop operations on XY files when multiple files or a folder with files is selected.

- Export of LMR files has been improved: materials defined as tables are no longer converted to a different wavelength grid, preventing unnecessary interpolation.

- Drag & Drop import of XY files has been improved: the file is now verified in a preview dialog, making it easy to confirm the import.

5. Interface and Evaluation improvements:

- Copy and Paste operations have been added to most database editors and are available via the right‑click menu.

In the Target and Measurement Editors, changing spectral characteristics through the selection dialog now keeps the values in the existing columns. This makes subsequent data modifications easier. - Direct access to the Chips configuration from the Environment panel has been implemented. It can be opened via the right‑click menu (Edit) or by using the small button next to the chip count.

- Color Monte-Carlo analysis now supports YI C and YI D65 Yellowness values.

- The Variator (RE) now includes the ability to link thickness errors across different layers.

- The concept of editing a Target or Measurement directly in memory has changed. When edited via the In‑Memory Editor on the Environment panel, Targets and Measurements no longer affect the database entries. In previous versions, such edits also modified the database. For all other objects, editing through the In‑Memory Editor continues to update the database, following the previous concept.

6. Materials and thicknesses:

- When a Material is replaced by the corresponding Vacuum Material in the Environment panel, the physical thicknesses of the related layers were previously updated after closing and reopening OTF Studio. They are now kept constant.

- Keep Physical Thickness design setting can be additionally controlled in the Configuration panel: Settings ribbon → General Options → Materials.

7. New COM interface: Added interface in order to provide the ability to obtain the information about the loaded conventional target, including the number of pages, characteristics, angles, wavelength ranges, and target values, tolerances, and qualifiers.

8. Fixes:

- Unit conversion was not applied to some of the displayed values in some specific configurations of values. Fixed.

- A false error message "Substrate not loaded" appeared in rare cases when the configuration of the CH had just started from the empty state. Fixed.

When Monte Carlo and Worst-case curves were plotted together, the Value + Confidence Interval line disappeared and was replaced by a duplicated theoretical curve from the Worst-case. Fixed. - Thickness Errors panel is now correctly updated after change of the Thickness units in the OTF Studio configuration.

- Fix: Corrected an issue in Targets where, under rare configurations, expressions and linked expressions were incorrectly mixed.

- When a layer material was replaced in a design loaded into memory, the optical thicknesses of the layers changed even though the Keep Physical Thickness setting was inactive. This issue has been fixed.

- Slight correction of a coefficient for D65/2° yellowness index definition (typo: 1.2965 instead of correct value 1.2985).

- Correction of mistypes in Hints and supplementary message dialogs.

25.72 (13.10.2025)

1. Interface Enhancements:

- Added Keep Only Loaded option to the Save As project dialog: only currently loaded items are retained in the saved file.

- Added LDD export (Bühler Leybold Dispersion Data) available in the Layer Materials Editor via right-click drop-down list.

- Monte-Carlo Spectral Evaluation now displays the theoretical curve alongside simulation results.

- Improved target presentation in the Angular Evaluation Panel — targets are now grouped by wavelength and plotted as functions of angle.

- Plotting Options: added Phase on Back Reflectance to the available 2D and 3D plot types.

2. Improvements of the Smart Brush cleaning algorithm: First layers with negligible optical impact due to similar refractive indices are now processed more efficiently.

3. Further improvements and bug fixing:

- Method Compatibility Control: Improved safeguards against incompatible combinations (e.g., Robust Synthesis with Multi-Start Generator).

- Fixed a rare access violation during termination of the Robust Synthesis.

- When a simple shift is used in the Model Builder, further selection of a more complicated Systematic model did not disable the shift option properly, if the group control check box is used (not the toolbar one). Fixed. Now the shift is deselected properly.

- Resolved a rare run-time error after complex layout operations (renaming, switching layouts using Layout Manager).

25.66 (29.09.2025)

1. Color features enhancement:

- Compare Designs functionality operates now in the Color Evaluation panels and diagrams.

- Replaced the Angles column with a new Type column in the numerical panels: Dominant wavelengths, YI, Complementary, Purity, CCT, Duv, and CRI. The new column displays both the characteristic and angle, providing a clearer context when multiple characteristics are shown simultaneously.

- Added display of colorimetric values—CCT, Duv, Complementary and Dominant wavelengths, Excitation Purity, CRI, and YI—for the loaded Target or Measurement. These metrics now appear directly in the Color Evaluation panels for improved analysis and comparison.

- Append Measurements operates now in Color Evaluation numerical panels and diagrams.

2. New interface features:

- Multiple layouts implemented. They can be controlled via Switch and Layout Manager options in the Settings ribbon.

- Added Next Cell on Enter setting (Settings ribbon → General Options → User Interface panel). If this checkbox is checked, the Enter and Ctrl+Enter keys navigate the selected cell in any spreadsheet.

- Added Modern Scrollbars setting (Settings ribbon → General Options → User Interface panel). When enabled, scrollbars remain minimal until the mouse pointer hovers over them, at which point they expand for easier interaction.

3. Enhancements of the laser-related options and phase-related features:

- Implemented time-domain pulse analysis: Pulses can now be calculated in the time domain following reflection from designed dispersive mirrors.

- Phase unwrapping option implemented: Settings ribbon → General Options → Phase units → Phase Unwrapping check box.

4. New feature in plots: Added support for OD units on the second axis: You can now specify Optical Density locally for the second axis, enabling simultaneous display of the same characteristic with different scalings in a single plot. Create a new Y-Axis via View ribbon → Axis2 and set OD for this axis through the sliding panel of the Evaluation plot.

5. New COM interfaces:

- Monte-Carlo with COM: three new properties added to allow the independent control of the active state of each of the parameter groups.

- COM support for multiple layouts.

5. Further improvements and bug fixing:

- Grid Generator is correctly set to the Turn Off state if a non-editable spreadsheet column is focused.

- Renamed Monte Carlo plot curves from “±σ” to “±CI” to accurately reflect their meaning as confidence intervals. The previous labels were misleading and suggested standard deviation.

- Fixed a rare bug that caused an exception during New Project creation or Import operations when certain previously opened projects were still active. This issue occurred only under specific conditions and has now been resolved.

- Fixed an issue in the Copy Numbers command when used in the Angular Evaluation panel. Fixed.

- Fixed display issues in the Specification editor: Complex specifications involving multiple areas on a single page were not rendered correctly. This has now been resolved to ensure accurate visualization.

- Fixed Smart Brush behavior: When Remove layers was active, designs could still include thin layers if other cleaning options—such as Remove insignificant layers or Reduce thickness—were also enabled. This conflict has been resolved.

- Fixed a rare issue with file transfers between systems using US or European language settings and those with East-Asian language configurations. Certain files previously caused unexpected behavior due to encoding or locale mismatches.

- Fixed display issue in copied items: When copying a Layer Material, Substrate, or Design item, the additional columns (Re, Im, N, TT) previously showed only NaN values. They now update correctly without requiring a project save and reload.

- Fixed inconsistent Y-axis settings in phase plots when the configuration limits were set to 0–360°.

- The partial merit function related to the integral target is returned correctly through COM.

- Fixed an issue in Target Generator: Wavelength limits were unintentionally altered after performing Delete Band or Insert Band operations.

25.56 (24.08.2025)

1. New synthesis algorithms and features:

- Robust Synthesis has been implemented. The algorithm settings can be activated and configured via the General Options panel (under Spec Methods → Robust Synthesis). Alternatively, settings can be adjusted directly in the Design Builder panel upon initial algorithm activation. Robust Synthesis can also be deactivated from the Design Builder panel. The perturbed designs are generated in a sophisticated multi-dimensional space, carefully engineered using proprietary know-how to reflect realistic design variability with high fidelity.

- The Rugate Synthesis algorithm has been implemented. It can be activated via the Rugate tab on the Synthesis ribbon. The special mixture material and rugate parameters can be configured in the Builder panel.

- The Smart Brush Algorithm (Cleaner) has been extended. The design can be made thinner by removing half-wave thicknesses at a specified wavelength from thick layers, used independently or in combination with other cleaning methods. A Deep Search version is also available for enhanced optimization.

- The merit function value has been added as an additional termination condition for the Gradual Evolution method.

2. Enhancement of features and tools for architectural glass:

- The new IGU (Insulated Glass Units) database has been added. IGU structures can be created, loaded, and unloaded. Several IGUs can be loaded simultaneously into the environment.

- When at least one IGU is loaded, the U- and g-values tab (Analysis ribbon) opens a special evaluation panel—a table displaying integral characteristics specific to IGU.

3. Interface improvements:

- New columns—N (Number of Layers), TT (Total Thickness), and TQWT (Total Quarter-Wave Thickness)—have been added to the Design Database. Their visibility can be configured via the General Options panel (Data page).

- Comments of the saved designs are now more informative: they include layer materials, number of layers, total thickness, and target names. Comments of the saved designs are now more informative: they include layer materials, number of layers, total thickness, and target names. Comments are visible at the bottom of each database panel. They can be switched off in the General Options panel (Data page) if they are not needed.

- Comments at the bottom of each database panel are now visible for all object types, including layer materials, measurements, targets, and others.

- The active tab in the Measurement/Target Editor uses a bold font, making the navigation more convenient.

- Variator sliders now include tooltip hints that indicate the percentage deviation of the current parameter value relative to its initial setting.

- Integral specifications have been implemented. These specifications can now be used separately or together with spectral and color specifications.

- From Integral Target feature has been added to the Integral Values configuration (Values panel). It allows you to configure the displayed integral values according to the loaded Integral Target.

- Refined depiction of spectral features in the OD scale.

- Improved legend and contour levels for easier interpretation of batch processing maps.

4. New color features:

- Implemented the Yellowish Index (YI) display in the Table panel under the Dom/Comp/Purity/YI tab, based on the ASTM E313 standard definition (YI, C/2° and YI, D65/2°).

- The Freeze option is now available for all color diagrams, accessible via the right-click menu on each diagram. This feature enables you to (i) compare color coordinates of multiple designs side by side; (ii) fix the color coordinates of a selected design to serve as a reference, and (iii) explore color changes introduced by the Variator, while keeping the original design's coordinates visible for comparison.

5. Enhancements in reverse engineering and characterization modes:

- Display of the integrals on measurements has been added to the reverse engineering mode. It is possible to select a weight function from the spectra database and calculate the integral values based on the measurement.

- Tooltips in RE and CH modes now display measured data. Measured data points are interpolated using a linear interpolation method.

- The capacity of the History panel in the RE mode is adjusted to keep results related to all positions (important when more than 100 positions are processed).

- Batch processing colour maps now indicate parameter levels and the legend in a more convenient way.

- Batch processing colour maps now support the display of both relative and absolute thickness errors, averaged across specified layers.

6. New features in the Optical Monitoring mode:

- Problematic monitoring layers, i.e., the layers where specified monitoring criteria are violated, are now shown not only inside the Runsheet, but also highlighted by magenta color in the signal plot.

- A new From Machine option has been added to the Marks tab. This feature automatically configures the criteria selections based on the currently loaded machine.

7. New COM interfaces:

- In-memory Integral Specifications.

- In-memory Color Specifications.

8. Further improvements and bug fixing:

- To help new users get started, OTF Studio now opens with a sample project on first launch.

- A minor issue in the Copy Numbers operation within the Monte-Carlo plot has been resolved. Previously, headers were occasionally misplaced in Excel after pasting the copied data.

- Target and Measurement editors occasionally froze when users attempted to enter negative values in the tolerance column. This issue has now been resolved.

25.45 (21.07.2025)

1. New features for large area deposition and mass production: New option to process XY scan measurement data (batch processing) and to visualize the results as contour maps. Multiple views (discrepancy function, thickness errors, actual thicknesses, relative and absolute thickness errors, refractive indices, and extinction coefficients) are possible.

2. Further enhancement of the interactive analysis tool:

- Variator in the AS and RE modes supports refractive index variations Per Layer; this allows exploring the effect of variation of separate refractive indices on spectral, integral, color, electric field, admittance, etc.

- Extinction coefficient (per material and per layer) added to the AS Variator.

3. New features for more convenient and fast operations with measurements:

- The Compare Measurements feature has been implemented, allowing multiple measurements to be compared on a single plot. This can be useful, for example, for comparing results from different deposition runs.

- Append Measurement feature enables you to append a measurement to the currently loaded measurement. The corresponding model curves are calculated correspondingly.

- The Scan Discrepancies panel has been added to display the discrepancy value for each measurement scan (for example, BBM measurements).

- Import of X, Multi-Y files is now supported for both Excel and text-based formats, such as CSV and tab-delimited files.

4. Further enhancement of reverse engineering:

- A linear model was added to the systematic thickness model.

- Linear and exponential models have been implemented in the systematic refractive index mode.

- A refractive index profile was added to the Profile panel. This feature is essential when inhomogeneity is used in the reverse engineering model.

- The Values panel has been added to the reverse engineering mode. The panel now also includes quantities for the IGU (Insulated Glass Unit).

- Refractive Index and extinction coefficient plots are now more convenient: after a zoom operation, switching to another view (e.g., individual materials) displays the chart in the original scale.

- Added the ability to configure whether offsets are applied to the refractive indices in the Save Design option (Results ribbon). If a linear or exponential model is used for offsets, the average offset is saved.

- A sliding panel has been added to the fitting panel to control axis settings and scaling. Tooltips are now available in the fitting panel.

4. New Optical Monitoring (OM) mode feature: Layers can now be displayed as color stripes. The selection is available via a right-click drop-down list in the signal plot panel.

5. Interface improvement: Hints for displaying the total thickness of each material have been added to the design editors in AS, RE, and OM modes. These hints appear when the mouse pointer hovers over the Design table footer.

6. New COM interfaces have been implemented to compute Solar, Light, and UV values according to EN 410 and NFRC standards. A new COM method was added to calculate the colors of the glazing.

7. Further improvements and bug fixing:

- InR values were not properly restored after loading a runsheet from the Runsheet database. Fixed.

- Fixed bug: Monitoring characteristic type and angle of incidence were not correctly saved in the runsheet database.

- In Multi-Environment mode, an item loaded to several environments was only updated in the active environment, while outdated values remain in others. Now, the Load operation updates all items with the same name across all environments.

- 2D, 3D plots bug fixed: when Re(n) or Im(n) of a material was used as X or Y axis, the resulting plot was incorrect. The first loaded material was used instead.

25.39 (22.06.2025)

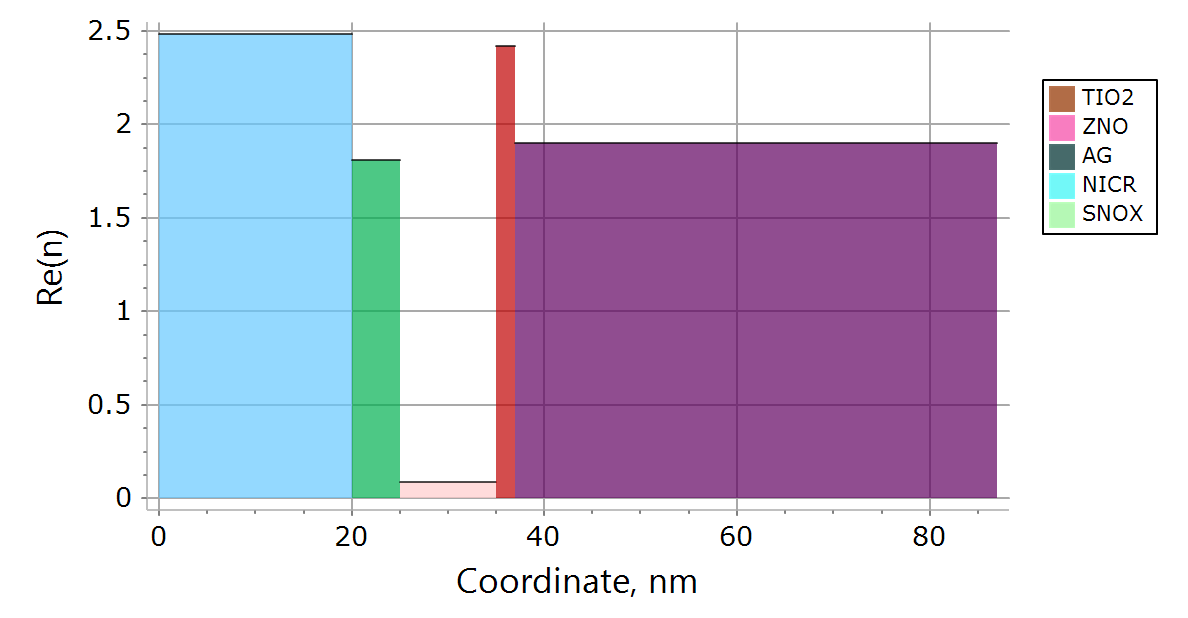

1. Configurable Reports Feature:

- All reports can be created in DOCX format, including plots and numerical values for design thicknesses. Powerful printing options and export to PDF format are included. You can configure a company logo, which will appear at the top of each page.

- The reporting feature is available in all OTF Studio modes.

- Reports can be edited directly in OTF Studio, just like working with standard *.docx documents.

- In AS mode, you can configure reports to optionally include units, environment settings, merit functions, evaluation plots, design panels, and design layer thicknesses.

- In OM mode, you can include units, environment settings, OMS signals, and OMS runsheets.

- In RE and CH modes, you can include units, environment settings, discrepancy functions, fitting plots, model plots, and layer error metrics.

- The Export Reports to Excel feature has also been implemented.

Illustration: Click Report (Doc) on the Results ribbon, configure output (what you want to include in your report), and press Commit. You can edit the report directly in OTF Studio. You can print the report or export it as a PDF.

2. Significant update of the Color option in the AS and RE modes: Specifying several characteristics (all combinations of R, T, and BR as well as polarization) for the simultaneous evaluation of colors is possible.

3. Import/Export enhancements:

- RE, CH modes: now the change of angle of incidence and measured characteristic (Agilent Cary import) affects the currently selected trace only, and it allows for configuring multiple measurements and importing them as a batch.

- Improved import of files with special symbols in file names from all other projects (other software packages, another OTF Studio project).

- Added *.csv files to the list of Excel import files for the RE and CH modes. It allows for the direct import of CSV files using Excel decoding, without external conversion by Excel from CSV to XLSX format.

- Export to Ansys Zemax OpticStudio implemented.

- Copy numbers in the OM mode have improved. Now it is possible to specify a thickness step for the output.

4. Values panel has been enhanced: now it is possible to change the colors and styles of each displayed Value type.

5. New features for Architecture glass:

- An Architecture Glass checkbox has been added to the User Interface panel (Settings ribbon → General Options). Activating this option enables specific features tailored for architectural glass coatings only.

- Additionally, the ability to use measurements (T, R, BR) as a substitute for a substrate has been implemented in AS and RE modes.

6. Extended Support for File and Object Names: The file system now supports arbitrary object names, including names of substrates, materials, designs, and more. Project file names can be case-sensitive, eliminating potential naming conflicts between identically spelled names with different capitalization (e.g., "NAME", "Name", and "name"). In the new version, these are treated as distinct entries.

7. Interface improvements:

- Hints to the bar diagrams to display layer number and thickness/error have been added in the AS and RE modes (design structure, error diagram).

- Rearranged Report tab group (Results ribbon) to provide better access to Doc, Excel, and Text reports.

- More informative. The plotted check box was replaced with Active when selecting the current Environment. Plotted explains the role of this selection better.

- Now it is possible to specify the width of the confidence interval in ±σ terms in the Monte-Carlo configuration panel. ±σ = 1 corresponds to 68.2689%.

7. New COM interface: A method to compute the spectral characteristics when the design top layer thickness varies.

8. Improvements and bug fixing:

- Copy-Paste operation in the Values panel: when the decimal separator in Windows is a comma (,), the copy operation copied NAN instead of the values.Fixed.

- Inconsistent Theory values in the Monte-Carlo Values evaluation panel. Fixed.

- The values of absolute errors in the Monte-Carlo configuration panel were rounded too strongly; fixed.

- In rare cases, color evaluation hung up in the case of simultaneous specifications with polygons and color differences. Fixed.

- In rare cases: slowdowns and hangs in the case of GDD on a vast scale and dashed line style. Fixed.

- Fixed: In rare cases, when a target or measurement with a highly narrow wavelength range was loaded last, the entire evaluation region would incorrectly shrink to match that limited range.

- In the case of a Multi-Environment configuration, the status Fixed was not reliably applied if configured in the Design Builder. Fixed.

- Improved optimization convergence in the case of complicated problems with constraints.

- More rigorous computations in the Gradual Evolution with Standard sensitivity allow for finding better solutions with a minor computational time increase.

- Further improvement of the CH mode Swipe algorithm to increase its reliability in finding the best fitting parameters.

25.33 (14.05.2025)

1. Enhancement of design features:

- Stress and Thickness targets have been implemented. Now you can optimize total coating thickness and thicknesses of individual layer materials and design stress-compensating multilayers. The implementation includes the evaluation of custom stresses based on the Stoney formula and profilometric measurements. Learn more in our YouTube videos.

- The BoundTrap design option has been implemented; the thickness limits for each material layer can be set in the new Methods section of the General Options panel.

2. Import features extended: Drag & Drop import of measurement option has been implemented. The measurement file format is automatically detected and correctly imported.

3. New in plotting: Expressions can be visualized in 2D and 3D plots. The list of available expressions is at the bottom of the Value Axis list.

4. Export to ODS format (Optical Design Specifications) has been implemented.

5. Enhancements of the Values panel:

- More convenient opening of the configuration sub-panel after clicking the [+] button.

- The Insert Rows tab inserts a copy of the selected value into the position above or below the current one.

- Setting Adjust plots and Values list on Integral Target load added (General Options panel).

6. New in Admittance plot: Iso-reflectivity curves can be added.

7. Enhancement of options for architectural glass:

- U, g, SHGC, and SC values of different standards can be displayed simultaneously in the Values panel.

- Improvement of NFRC U-value calculations in the case of gas mixtures in the gaps.

8. The application of Sellmeier models was improved to avoid non-physical solutions with negative coefficients.

9. New in OM Mode: Step setting has been added to the IR Strategy; it allows control of the accuracy of the obtained wavelengths.

10. Other Improvements:

- In some cases, TOD curves exhibited sharp spikes if one of the layer materials was specified as a table (the spikes are present when the presentation grid nodes are very close to the table wavelength points). The issue is resolved.

- Electric field targets: automatic copy of the previous page when adding a new page.

- The weight of the electric field target is now not reset if a new one is loaded.

- The Keep Physical checkbox immediately affects the transition between thicknesses in the Design Editor. In previous versions, the effect was activated only after Commit.

- Names of Mixture materials and other special types are correctly displayed on the corresponding Material editor tab. It removed possible confusion about the specified material.

11. Bug fixing:

- Fractions were incorrectly displayed (empty field instead of values) in the Material Mixture tab. Fixed.

- Multi-Start (Design vicinity mode), potential problem with constraints misalignment fixed. The problem decreased the performance of the method in some configurations.

- The layout restore multi-monitor problem has been fixed. In the previous version, such panels remained invisible when a floating panel was positioned at the secondary monitor and the monitor was detached (a typical scenario for notebooks). Now they are moved to the primary monitor if the secondary monitor is missing.

- Color Values in the Values panel were not updated after changing the configuration's color parameters (Observer, Integration step).

- A minor bug in the Stack editor has been fixed.

25.27 (19.04.2025)

1. My Catalog feature for layer materials and substrates was implemented:

- You can store your spectra, substrates, and layer materials in a centralized location, which can be configured in the General Options → Data panel. Additionally, you can save substrates, layer materials, and spectra using the To My Catalog tab, accessible via the right-click drop-down menu.

- You can import layer materials, substrates, and spectra from your own catalog (Import ribbon → My Catalog).

2. New functionality of the Compare Designs feature: The Compare Designs feature now supports the Values panel. This panel aggregates integral, averaged, color, and other values from the design database, current design, and designs in the History and Collection panels. You can effortlessly export this data to Excel using the copy-paste function.

3. New design feature:

- Electric field optimization is now supported through Gradual Evolution and Needle Optimization methods.

- The Values panel now includes the contribution of the electric field target to the merit function.

4. Enhancement of color block:

- CIE UCS 1976 Color diagram has been implemented.

- CIE C*hs and CIE H°LC color diagrams have been implemented.

- The Color Target (color measurements in the RE) is now factored into the discrepancy value during reverse engineering. This enhancement allows for incorporating color value measurements into the reverse engineering process.

5. Enhancement of features for architectural glass.

- OTF Studio now supports calculating SHGC and SC values by the NFRC standard.

- You can now choose from three available standards: EN 410/673, NFRC Winter, and NFRC Summer.

6. Enhancement of the Interactive Analysis Tool (Variator): you can link layers and vary them simultaneously as a group through the new Link column. The Replace feature (hotkey Ctrl+H) has been introduced. This feature enables you to replace values in columns effortlessly. For instance, you can simultaneously change a target value from X% to Y% across all spectral regions by replacing all X% values with Y%. This functionality also applies to designs, measurements, spectra, dispersion tables, etc.

- Upon opening, the Start field is automatically focused, enabling faster workflow by eliminating the need for tabbing or mouse clicks to activate the field.

- An Apply tab has been added to all editors, allowing you to update database content seamlessly without closing the corresponding editor.

8. Interface improvements:

- High-contrast theme enhanced: Enjoy the improved appearance of interface elements in this theme, including sliders, panels, and Builder panels.

- Auto-Hide and settings retention: The Auto-Hide feature, Quick Access Toolbar position, and Ribbon group display settings are now saved and restored across OTF Studio sessions for a more seamless user experience.

- Copy operation (Ctrl+C) in OM: This functionality is now accessible via the right-click drop-down menu in the spreadsheet preview panel.

- New Copy Image tab: Added to the right-click drop-down list, this tab simplifies transferring plot images directly to the Windows Clipboard.

- A new Save Unused Materials checkbox has been introduced in the Save LMR file export options, allowing you to decide whether to include unused materials.

- When the Compare function is active, the panel displaying compared plots or values can be closed and reopened as needed, with all items for comparison being restored correctly.

9. New COM interfaces: Added COM interface to set or obtain U-, g-values calculation standard (EN, NFRC Winter, NFRC Summer).

10. Bugs and inconsistencies fixing:

- The Edit tab on the Multi-Coating panel opened the wrong editor when the Resulting Target was selected. Fixed.

- Fixed a problem in configuring the Color target with COM interfaces.

- The headers of the Color Evaluation panel were not correctly updated after the change of Observer and other color configuration settings in the General Options dialog. Fixed.

- In the case of Expressions in Targets or Specifications, legend captions were inconsistent for very rare complicated configurations. Fixed.

- The E-Field optimization did not work if the E-Field target specified a material not used in the current design.

25.22 (22.03.2025)

1. New design features:

- New settings in layer materials allow you to specify the lower and upper limits for their layer thicknesses. Once determined, these settings can be used in all features related to the prefill of constraints. With this approach, the Lower and Upper columns in Prefill can be linked to layer materials. This helps reduce repetitive constraint settings in many situations, mainly when designs consist of multiple materials, each with its own constraints.

- Constraints for the layer thicknesses were implemented in the Multi-Start design algorithm (Generator, Constraints panel).

- The ability to set layer thickness constraints has been implemented in the Multi-start design algorithm (Vicinity). The prefill option can specify these constraints as a percentage or by linking them to material thickness constraints.

- The Prefill option in the Refinement with Constraints algorithm allows you to specify lower and upper thickness limits either as a percentage or by linking them to material thickness constraints.

2. Updates to Import/Export options: The export of all reports to MS Excel and the import of measurements from MS Excel have been redesigned. Reports can now be exported directly to an Excel file without intermediate copy-paste steps. Additionally, all Excel-related import/export operations have been significantly accelerated. MS Excel is no longer required to be installed on the computer or virtual machine. For example, you can create a report in an Excel file on a computer without Excel installed and then transfer it to another computer with Excel. Or you can import a measurement from an Excel file (for example, in a clean room).

3. Update in Optical Monitoring mode (OM): A correction factor setting has been added to the layer material (see the Additional tab). These values can reset correction factors in the monitoring run sheet via a right-click drop-down menu in the Corr column.

4. Preprocessing enhancement in the CH and RE modes: The ability to exclude measurements with angles of incidence outside the specified limits has been implemented. This feature is handy when the original measurement file includes data for multiple angles.

5. New COM interface supports the angular limits in the preprocessing.

6. New interface features:

- The thickness units selector (Physical, Optical, or QWOT) has been implemented and can be accessed through the right-click menu in the Collection/History panel.

- A summary display has been added, showing the total of the lower and upper constraints in the constraints column. These values assist in estimating the expected total thickness.

- The flickering of the Hint window, which displays the thicknesses of each material in the design, has been eliminated.

7. Update in U- and g-values: loading glass measurements is now possible.

8. Bug fixing:

- Active Compare mode was still active in the database views after switching to another OTF Studio Mode. The Compare mode is deactivated during the switch to avoid confusion.

- A rare exception happened in the General configuration dialog when the material colors were adjusted. Fixed.

- After switching to the OM mode from the AS mode, unused materials abbreviations were present, but names were blank in the Environment panel. Fixed.

- OTF Studio displayed empty panels after restarting when a floating panel was present while saving a project file. Fixed.

- A rare access violation exception occurred after cleaning AS environments when some deleted items were used in the OM mode configuration. Fixed.

- Multiple Environments remained in the Environment panel after switching from AS to RE or CH mode. Fixed.

- When units are switched in the Variator via the right-click menu, OTF Studio sometimes displays errors. Fixed.

- Wrong naming of meta-tags during the import of Agilent Cary files. Fixed.

25.18 (09.03.2025)

1. New design features:

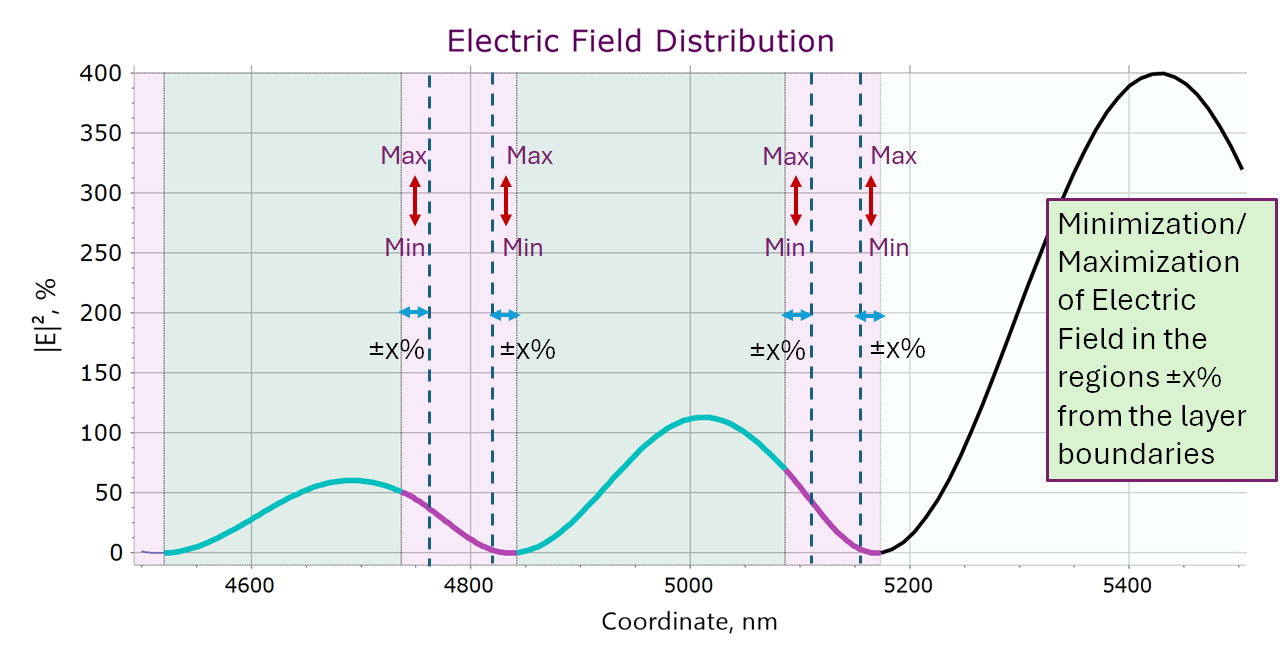

- A flexible and powerful Electric Field target is implemented in AS mode. You can specify the wavelength grid, polarization, incident angle, layer material, and optimization goal. It is also possible to define the specific layer region where E-field optimization is applied. This region can be around the layer boundaries (with a configurable boundary indent) or around the layer center. Different optimization goals can be specified for different wavelength/angular ranges.

- Refinement algorithms were extended with a slowly converging variant (Slow check-box on the Design Builder).

- Extended Expressions now support environments, allowing you to connect advanced expressions to different environments and incorporate them into the final composite expression.

2. Color enhancements: The Color patch feature is implemented. The Color Patch can be accessed via the corresponding tab on the Color panel or the special tab under View → Color.

3. New analysis feature: The Design Builder in AS (including all panels such as the Variator) and the Model Builder in RE (Variator) can display design thicknesses in Physical, Optical, or QWOT units based on your preference. You can configure this setting in the General Options panel or quickly access it through the right-click drop-down menu on the design table.

4. Monitoring enhancements: Backside option added to the Chip configuration. Now it is possible to exclude the backside reflection effect.

5. Admittance plotting improved:

- Plot settings are now saved within the project.

- Admittance series names are more informative, displaying the layer number and polarization.

- Tooltips and axes names are included in the admittance diagram.

6. Interface enhancements:

- The Copy operation now separates Signal Change column values in OM mode. When pasted, the values are distributed into separate cells.

- Docking of tabs in the Fitting window has been improved. An unnecessary caption has been removed, appearing in some rare cases after extensive docking and undocking separate fitting tabs.

- The height of the plot configuration (sliding panel of the evaluation window) is updated to fit all configured plots (both for Y- and Y2-axes).

- The Color Differences tab has been added under the Color tab in the View ribbon, enabling quicker access to this panel.

7. Bug Fix: After removing a material from memory, designs referencing this abbreviation remained in the history/collection. This issue caused errors during the Extract operation and has now been resolved.

25.15 (17.02.2025)

1. New plotting feature:

- The Axis2 option has been added, including a second Y-axis in any panel evaluating spectral characteristics. Both spectral and angular panels are supported. Curve configurations can be managed via the right sliding sub-panels of the respective panels, and tooltips support all configured curves. Additionally, the Axis2 feature is available in the right-click drop-down list of these panels.

2. New analysis features:

- Admittance panel added. The panel is controlled similarly to the E-Field panel: the calculations can be performed concerning the AOI and the wavelength; the wavelength range, wavelength step, as well as polarization state(s) (s-, p-, both) can be specified.

- Using the Display Limit checkbox and the number of top layers setting, you can specify how many last layers should be used for admittance calculations. The default setting is unchecked, i.e., Admittance is calculated for all layers.

- The Colors of curves on the Admittance panel correspond to the colors assigned to layer materials in Settings → General Options → Materials configuration.

3. Monte Carlo and Worst Case Analysis:

- Worst-case performance is possible with Monte-Carlo simulations, representing plots at the same resulting plot. To activate the Worst Case, switch the toggle Add Worst Case. The Worst Case can be calculated separately through the Worst case tab on the Analysis ribbon.

- Refractive index variations and Substrate/Incident medium variations have been implemented into the Worst Case Performance calculations.

- Monte Carlo adjustment: variations of layer material refractive indices are now performed not on a per-layer but on a per-material basis.

4. New evaluation feature: the Filter tab was added to the right-click drop-down list of the Evaluation panel. It opens the Filter Parameters table, displaying key filter characteristics such as central wavelength, maximum value, FWHM, slope, QZ, QC, QT, and more. The spectral data for the evaluation is sourced from the first curve plotted in the Evaluation panel.

5. Monitoring enhancement: Added Initial Readout Corrector. It sets the Initial Readout value equal to the final readout of the previous layer.

6. Improvements in the RE and CH modes:

- Added the Correct non-physical values option to the Preprocessing configuration. This option ensures that T and R values are within the 0 - 100% interval.

- Computational issues have been prevented in cases where a loaded material is defined by a formula that contains a singularity within the measured wavelength range.

7. New feature in the History and Collection panels: Re-Evaluate all MF and Quality values recalculates merit function and quality values of all designs in the History and Collection panels. This option is practical after modifying/reloading the target.

8. Interface improvements:

- Right-click drop-down list is available only for the editable columns.

- Design To Formula function improved for cases when multi-character abbreviations like chemical formulas are used.

- When one or more panels were floating, database operations were sometimes assigned to the wrong database. For example, the design database was used to open files instead of a floating stack database. Fixed.

- Improved user interface with the OTF Studio plots and panels: now it is easier to resize them, especially on high-resolution monitors.

- Remove layers thinner than the parameter, which was not updated correctly after the length units changed. Fixed.

- E-Field tab moved to the Analysis ribbon.

- Corrected yield evaluation inconsistencies in cases when specifications were on several pages, with coinciding wavelength values used.

- Fixed Open File inconsistency after switching a mode and opening the same file.

- The progress bar with Yield results is closed when the Yield panel is closed.

- Quality value display corrected when only color specifications are loaded.

- Added more informative captions in a spreadsheet exported through the Clipboard (Worst case and Monte Carlo panels).

25.11 (01.02.2025)

1. New features:

- The From Design tab has been implemented into the Design Formula panel. It generates the formula representation of the current design.

- Click on the monitoring signal curve to focus on the corresponding wavelength in the monitoring runsheet.

- The Combine option has been added to the Design Editor. It controls whether the adjacent layers of the same material are combined or not during the Commit operation.

- The Bounds Check tab has been implemented: the tab is available at the right-click drop-down list of the Design Table (Design Builder). It controls whether the constraints can violate design thicknesses during Refinement with Constraints. When active, Constraints are modified so as not to disturb the current design.

2. New COM interfaces:

- Import from catalog method importFromCatalog (ISPectrum, iLayerMat, Isubstre interfaces).

- Function getIntegralValue outputs a result in the current units, corresponding to the requested characteristic.

- COM interfaces supporting U- and g-values.

3. Interface improvements:

- Added a diagnostic to the Yield panels for the situations when the current design becomes invalid for Yield analysis (Quality < 100%). It can happen if the design or the environment is changed after the Yield panel has been opened.

- Gradual Evolution is terminated if the merit function value is already almost 0.0 (independent of termination criteria).

- Mathematical formulas are now displayed with improved technique, providing better style and readability of expressions.

- Displaying of formulas improved on screens with different resolutions.

- Filter design: text tooltips were added to display transmission and rejection levels in % instead of dB. They appear when the mouse hovers over the related captions.

- Tooltips in Monte-Carlo are now consistent with the selected visualization (Statistics or Results).

- LMR export has also been added in the AS mode.

- The Environment panel becomes focused in a tabbed configuration if the Environment tab is called on the View ribbon.

- Column Editor and Grid Generator can be called from the right-click drop-down list of the Monitoring runsheet panel.

- Display of Monte-Carlo values results was improved: When the merit function without a target was used, it displayed -10e-2 values, but now "n/a" is correctly shown.

- A progress indicator has been added to the Monte-Carlo Values panel. It can be important if many values are specified, and some of them require lengthy computations (like averages over angle and wavelength ranges).

4. Bug and inconsistencies fixing:

- In rare cases, a computational error occurred when specific color targets combined with linked targets requirements were used. Fixed.

- Fixed error on attempt to edit local coatings in a Stack.

- The design cross-section view was not dependent on the Thickness units setting, fixed.

- Filter design settings (central wavelength, shape factor, etc.) were not dependent on the units (nm, μm, Å). Fixed.

- Positions and size of text tooltips on the 2nd monitor corrected.

- If multiple environments were used, loaded targets were not updated due to changes in the active environment. Fixed.

- Inconsistency in the Design Editor (Formula): if an extra blank is inserted between the @ sign and the local wavelength value, the result is multiplied by 1000 (if current units are nm). Fixed.

- The Number of Value column was empty in Monte-Carlo simulations of values. Fixed.

- In very rare cases, an error occurred in Refinement with Constraints if several groups were defined and some layers were assigned to these groups, but simple (not group!) constrained refinement was used.

25.08 (18.01.2025)

1. Color block enhancements:

- Range Color targets specified by convex polygons are implemented. It is possible to position the vertices with a mouse and to import data from external X/Y files (comma or TAB separated).

- Range specifications, defined as either convex polygons or using qualifiers, have been added to the Color Specifications.

- A converter from color targets to color specifications has been added to the Color Options drop-down menu in the Color Specification Editor. This feature extracts all eligible color targets and assigns them to the currently active specification editor.

- Linked Color Targets have been implemented. These targets enable the linking of target colors to the color of a specified spectral characteristic.

- Yield Analysis (Monte Carlo type) has been implemented for color specifications.

2. New Analysis features:

- Yield Analysis (Monte Carlo type) has been implemented. The feature also includes an for better visualization of the results.

- A Worst-Case Analysis option has been added. This feature displays the minimum and maximum deviations of the spectral characteristics of disturbed designs from the theoretical design curves.

3. Import options:

- Updated Hitachi spectrophotometer import to the latest Hitachi standard (UDSS files).

4. The Create from Measurement feature has been added to the Substrate Editor (accessible via the right-click drop-down menu). This feature allows for the quick creation of an n and k table from quasi-normal reflectance and transmittance measurements. The measurements must be provided in two separate X/Y files (*.csv, .dat, .txt, or tab-delimited format).

5. Interface improvements:

- Values in the Values list can now be ordered by number.

- Color coding has been added for measurements and theoretical curves corresponding to different angles of incidence. Additionally, the legend for measurements now includes the angle values.

- When a panel is opened in tabbed style and is not visible, selecting the corresponding option in the Ribbon menu brings that panel to the forefront as the top tab.

6. Bug and inconsistencies fixing:

- The E-Field plot automatically becomes ineligible if a stack is loaded after a design.

- Fixed model status (a checkbox on the caption of the model name unchecked) was not working properly in some cases. Fixed.

- Sensitivity analysis computation had several minor bugs. Fixed.

- In certain cases, the L*a*b* diagram was not updated correctly when the Observer or Reference White was changed.

- In some cases, Batch processing displayed wrong values in Batch View plots - Absolute and Relative thickness errors. Fixed.

24.61 (14.12.2025)

1. Monochromatic Monitoring enhancements:

- Machine database was implemented. The elements of the database (Machines) collect features and settings of the monitoring process.

- The first Strategy Generator is implemented: the monitoring wavelengths can be generated automatically using settings specified in the loaded Machine. The number of different monitoring wavelengths is limited only by the number of design layers. The calculations are extremely fast even for a large number of monitoring wavelengths.

- Amplitude column is added to the Monitoring Runsheet panel.

- Infrared monitoring strategy is implemented.

- Marks feature (Monitoring ribbon) is implemented: the feature allows indicating violation of the criteria specified for the strategy generation.

- New monitoring configuration settings introduced: InR persistence (Keep Initial Readout constant on updates), Essential Macleod swing definition (checked or unchecked), checkbox Show Signal until the &Next Extremum, and the number of digits in the Monitoring Runsheet signal.

- Export to Macleod CSV format.

2. Synthesis enhancements:

- Three new targets were added: differential phase shifts between p- and s- polarization on Reflectance, Back Reflectance, and Transmittance (for laser applications).

- Taper values can be now in the range from 0.0 up to 10.0.

- Consistent operating of constrained optimization if the number of design layers was changed during the refinement.

3. Interface improvements

- Chip column excluded from the visibility configuration of the Monitoring Runsheet since this column should always be visible.

- Signal plots modified to avoid overlapping of the gray lines representing the next layer signal.

- More convenient operation of all sliders in Variators and Runsheet option.

4. Bug fixing:

- In very rare cases, the Design Editor was opened in simple mode without the ability to use the "More" function if the initial configuration required the use of extended mode (for example, a material with inhomogeneity is included). Fixed.

- In rare cases, Sensitivities in the Model Builder were not updated if measurements were unloaded or changed. Fixed.

- In rare cases, chip selector tabs in the Signal plot were not shown, even if multiple chips were used. Color target representation on the Color diagram is now correctly updated when the active environment changes.

Unload Design and Unload Material operations improved in the OM mode.

24.57 (26.11.2025)

1. Enhancement of monochromatic monitoring options (OM mode):

- The Spectral, Contour and Surface panels have been implemented, allowing the presentation of signal dependency on thickness and wavelength.

- Various import options have been implemented into the OM mode.

2. Design and evaluation options enhanced: Multi-Environments have been implemented.

3. Manual Mode for the Smart Brush algorithm added.

4. Interactive analysis (Variator): correction factor variations and control wavelength variation now also change design thicknesses in the Design Builder table.

5. Accelerated export of large datasets to Clipboard (Copy Numbers feature with large number of points to export).

6. Interface improvement: it is possible to use the same color for the pattern and for the foreground in order to obtain solid look of the bars.

7. Issues of the Values List panel:

- In some configurations conventional target part was evaluated incorrectly. Fixed.

- Some combo boxes included unnecessary items if the configuration dialog was used multiple times.Fixed.

- The constraint ± 1000 on the Integral Target values removed.

8. Bug fixing:

- Interactive analysis in the Multi-Coating mode: changes in the Re(n) offset did not affect the spectral characteristics. Fixed.

- The unnecessary Tolerance column in the Specification Editor (Expressions type) has been removed.

- Variator issue is fixed for the case when one of the layer thicknesses is zero.

- Wrong number of parameters for the Random model, if this model is unchecked. Fixed.

24.53 (09.11.2024)

1. Enhancement of batch processing:

- Various plots of obtained parameters: systematic errors, layer thicknesses, and discrepancy values.

- Keeping the results in memory between OTF Studio runs.

- History of results with the possibility to plot fitting related to separate positions.

2. Combining layers of the same materials after saving the design.

3. Spectra (illuminant, detector) are now considered also in the RE mode. The corresponding option should be activated in the configuration.

4. Enhancement of the optical monitoring mode (OM):

- Links column is added. If links are active, the monitoring wavelength is changed simultaneously for all selected layers.

- Ability to load materials and light source independently from AS mode, the configuration is correctly saved and restored between OTF Studio sessions.

5. Enhancement of import/export options: Shincron export is implemented.

6. When the Copy option is applied to a chart, it copies not only the bitmap to the Clipboard but also the metafile and a text representation of all numerical information in the chart. In Excel, to insert either the bitmap or the metafile, use the Paste Special command. To copy numerical values, use Paste command.

7. Normalize Source and Detector option (Plot group of the Configuration panel). It is ON by default. Normalization helps to prevent unusual values of R/T during computations if a non-normalized illuminant or detector is loaded to memory.

8. Improvements of Multi-Coating mode: sometimes it was impossible to change the loaded design. It happens when a secondary (hidden) design field references a design missing in the Design database (for example, a deleted design). Fixed.

9. Interface improvements in the CH and RE modes:

- Unnecessary fields in the Substrate Characterization Model Builder are removed.

- Model Builder displays the number of active parameters in each of sub-model.

10. COM improvements:

- Save function saves a file with changed name.

- Wait function blocks computational calls more effectively.

11. Del key removed rows of a spreadsheet instead of the clearing the current edit field. Fixed.

12. Communication enhancement:

- Configurable E-Mail option (Help ribbon) to send questions with related technical information, screenshots, and project files (configurable) is implemented.

- Check updates feature is implemented.

24.50 (20.10.2024)

1. Multi-QWOT Filter design algorithm developed: This algorithm enables the design of narrow-band pass filters with a quarter-wave structure, where the layers are multiples of a quarter wavelength. The feature can be accessed via the Design Builder or the Synthesis ribbon.

2. Timestamp columns within the History and Collection panels: The History and Collection panels include additional columns for Date, Time, and Quality, which are hidden by default. The visibility of these columns can be managed through a tab within the History/Collection panel, and this setting persists across OTF Studio sessions. The Date and Time settings are useful for tracking long computations that may take several hours.

3. Design Report options improved: if no target is loaded, the design report will display spectral values based on the grid specified in the additional Design Report options.

4. Improvements in the Monte Carlo Colors feature: better synchronization between settings on the Monte Carlo Color Simulation Settings panel and the setting on the Monte Carlo Color panel.

5. Compatibility issue with old Office 2016 discovered. Advice: upgrade MS Office 2016 to a newer version to avoid compatibility problems.

6. The New (project) tab now creates a default layout of panels instead of an empty layout.

7. The export to LMR files has been enhanced with an optional conversion feature. Now, when a material's definition includes a formula, OTF Studio will prompt whether a conversion to a table is needed. If conversion is required, the user will be asked to provide the grid parameters.

8. Bug fixing:

- The header of the Monte Carlo Color panel (Table view) did not update after changes were made in the settings on the right panel. Fixed.

- More... option of the electric field evaluation: if the Max value was changed not by the spin-box but by typing the numbers, the wavelength range was not updated. Fixed.

- When a stack was loaded, color diagrams did not displayed its name in the Name column, but an empty field instead. Fixed.

- Inhomogeneity settings of maximum allowed deviations were not saved in the model in the RE mode. Fixed.

- Export to LMR files was blocked in some specific cases. Fixed.

- When a design with another material, but with the same name was loaded to the Environment in the RE mode, Reverse Engineering Model Builder did not update properly. Fixed.

24.46 (01.10.2024)

1. Enhancements of graphical and analysis tools: 2D and 3D plots to display various types of dependencies:

- Spectral characteristics vs. wavelength, phase characteristics vs. wavelength;

- Spectral and phase characteristics vs. AOI;

- Spectral and phase characteristics vs. offsets in refractive indices and extinction coefficient offsets of layer materials, substrate, and incidence medium;

- Merit function, electrical field vs. offsets in refractive indices and extinction coefficient offsets of layer materials, substrate, and incidence medium;

- Spectral and phase performance vs. coating coordinate;

- Merit function, electric field vs. coating coordinate;

- Color coordinates (all color spaces) and color differences vs. AOI;

- Color coordinates (all color spaces) and color differences vs. coating coordinate or thickness of a selected layer;

- Color coordinates (all color spaces) and color differences vs. offsets in refractive indices and extinction coefficient offsets of layer materials, substrate, and incidence medium.

- 3D plots are rotatable.

- 3D plots can be displayed as contour or surface types.

- Chart Designer operates for all plots, including 3D plots.

- Extremely fast computations and updating plots.

- All plots are updated when interactive analysis is used (Variator mode).

- Using this newest 2D/3D feature, you can customize your layout by combining multiple plots (2D, 3D).

2. Interface improvements:

- Improved import of X/Y data, when the selected folder has files of other types (not only text X/Y).

- The central wavelength for the surrounding variation group is now preserved and kept as configured in the general configuration dialog.

- Login and logout from the User account (Windows) can cause internal changes to the decimal separator setting in OTF Studio with undesirable results. Fixed. The internal setting for the Decimal separator remains constant.

24.44 (21.09.2024)

1. Interface enhancements:

- Right-click drop-down list added to History/Collection panels with main related commands.

- Capacity of History and Collection panels can be also controlled with the right-click drop-down. Possible capacities are 100, 250, 1000, 2500 items.

- Open Project function now also sets the Mode of OTF Studio according to the mode saved in the Project file.

- Size of buttons in the Model builder decreased to avoid multi-line layout.

- Better updates of U-, g-values after change of configuration or settings.

- Fit operation (RE mode) checks that at least some model is selected, and if not, an error message is displayed. It allows to avoid possible confusion on not working fit procedure.

2. Enhancement of design algorithms:

- Gradual Evolution and Needle Optimization methods were further improved to accelerate convergence.

- The Multi-Start algorithm was enhanced to prevent thick solutions.

3. Formula to Table convertor has been implemented to the Substrate editor and Material editor.

4. New COM interface: Meta-tag types and configuration can be controlled through COM.

5. Bug fixing:

- When a database is empty, the action tabs like Copy, Rename, etc., are not immediately activated after creating a new database item. Fixed.

- In some cases, Column Editor and Grid Generator were opened with empty, useless content. Fixed.

- When the Design Builder control was undocked (floating panel), the Variator tab was not working. Fixed.

- Copy and Rename operations ended without warning when the initial name was not changed in the save dialog. Now, an informative error message appears in such cases.

- Import to Essential Macleod had the wrong hint text on the Import ribbon.

24.41 (29.08.2024)

1. Batch processing for Position-type measurements in RE mode has been developed. When Position-type measurement data and a selected coating/layer model are loaded, the Batch tab on the Reverse Engineering Model Builder panel allows you to apply the model to all positions simultaneously. The results (correction factors) can be easily exported to a text file or Excel.

2. Fast export tab has been added into Design Editor allowing you to export the design into a *.txt format of X/Y type.

3. Enhancements:

- Synthesis with inhomogeneous layers is enhanced and converges faster

- Mode switching has been made more convenient: there’s no need to decide whether to save the current project file. The modified status is automatically preserved across all modes.

- Plotting of Evaluation plots accelerated.

4. Bug fixing:

- In some rare cases, it was not possible to switch between OM and AS modes. Fixed.

- COM initialization bug (24.40 version) fixed.

24.40 (24.08.2025)

1. Angular plots have been implemented and can be accessed through the View ribbon (AS mode) → Angle. These plots allow for the visualization of angular dependencies for spectral characteristics, phase, GD, GDD, and Expressions. Multiple angular plots are supported.

2. Freeze (curve) option has been added to the Evaluation panels (AS mode). It allows to keep existing theoretical spectral curves in the plots even when the design or configuration changes.

3. Tooltips have been significantly improved: they display better the numerical values for each of the theoretical curves. Now, the numerical values of the spectral characteristics when you hover the cursor over the relevant point are displayed automatically, i.e., "old tooltips" are active by default.

4. Tooltips and Freeze in RE and CH: both features are accessed also through the right-click drop-down list of Fitting plots.

5. Significant enhancement of docking: Docking of panels and plots is now more flexible than ever, allowing for any customizable layout. Plots and panels can be arranged vertically and horizontally in any order. Very complex layouts are possible now.

6. The Design Recipe feature has been integrated into RE mode. This feature allows for the automatic saving of designs after reverse engineering, with adjustments for layer thickness correction factors (Results ribbon → Recipe). The thicknesses from the Recipe can then be used for the next deposition run. After this run, reverse engineering can be performed again to determine any new errors in layer thicknesses. The Recipe design should be loaded as the starting point for this process. The reverse-engineered design can be saved as the Recipe for the subsequent deposition run. During the saving process, Recipe designs are automatically named in a way that makes it easy to track the entire sequence of recipes. The Design Recipe feature significantly speeds up the workflow.

7. Export to LightTools Design and LightTools Spectra (Coating) have been implemented.

8. Now, LMR export is supported in OM mode only, since for LMR the runsheet of monitoring is required. Therefore non-supported LMR export tabs have been removed from the Results ribbons in AS, CH, and RE modes.

9. Interface improvements:

- Selection of target spectral characteristics in the Target Editor is now more convenient: you can select an item with just one click, whereas previously, two clicks were required.

- Import from Catalogs is more convenient: the first item is not selected on initial display of the Import panel.

- Negative AOI are formally allowed in the Measurement Editor (they are imported as negative from Agilent Cary measurement data files, for example). Internally, however, these values are converted to positive, as the direction of incident light is irrelevant for the models being considered.

10. Bug fixing:

- Inconsistency of phase plotting when phase limits are 0 - 360° are fixed: in some cases the resulting phase was plotted as a constant; now, it can be plotted correctly only with Y-Axis auto scale settings.

- Computational problem fixed: it happened when stacks used with inhomogeneous materials.11.

11. RefractiveIndex.INFO import uses now the updated database (latest status, August 2024).

24.38 (11.08.2024)

1. Significant progress has been made in multi-scan import and batch processing. Measurements that include multiple scans or positions are now organized as objects, allowing for flexible editing and loading:

- This feature enables the import of multi-scan measurements and saves them as individual objects. This allows multiple BBM measurements to be stored within the same project without intermingling. It is possible to switch between Multi-scan edit and edit of separate measurements.

- Multi-scan files with Meta-tags of Position type is now supported. It is possible to activate any of the available positions and to bring it to the Model processing of RE mode. This feature is especially valuable for large-area depositions and batch processing.

- The Multi-Scan import option has been extended to support the Agilent Cary measurement data files, which include Position-type measurements. OTF Studio automatically recognizes the positions associated with the measurements, making this feature particularly useful for reverse engineering and the characterization of large-area coatings in batch processing.

- Multi-scan mode in all types of supported spectrophotometers selects all available items by default.

2. Progress in characterization algorithms and features:

- Higher order inhomogneities added to the CH Model Builder.

- More informative and practically useful thickness dependence of the refractive index is plotted instead of the inhomogeneity factor in the refractive index panel.

- Copy Numbers feature was added to the Profile panel

3. Horiba ellipsometric data import update: support of modern format has been added.

4. QWOT units are now used in the Thickness Errors panel (RE mode).

5. New COM interfaces:

- IPreprocessing interface allows to make measurement data preprocessing automatically

- IsBusy property is added: it determines whether computations are already or still running

6. Bugs fixing:

- Color Specifications Editor: Difference setting was not stored after change in the dialog. Fixed.

- Target/Measurement previews were not updated on units change. Fixed.

- Empty "Preview" panel appeared when switched to RE or CH mode from another mode. Fixed.

- The loaded data for a layer material was previously subject to unnecessary truncation based on the model's re(n) and im(n) limits. This truncation was inconsistent with the assumption that loaded data should be retained as is, without any modifications. The truncation has now been removed.

- OTF Studio 64 bit hanged if ellipsometry curves are evaluated for the empty environment due to uncertainty 0/0, since there is no reflected light in such configuration. Fixed.

- A very subtle and rare bug revealed and fixed. At some laptops, 64 bit version raised a GDI+ exception during startup.

24.35 (22.07.2025)

1. Stack options (analysis, synthesis) are implemented. Stack is an assembly of substrates (media) and coatings. Each substrate may be coated or uncoated by multilayer(s). Each substrate can be parallel or wedged.

- Calculation of spectral characteristics of stacks

- Calculation of colors

- Calculation of integral values

- Monte-Carlo simulations

- Copy numbers and stack reports

- Synthesis of stacks

2. Import of multiple measurements recorded in the course of the coating deposition, for example, multi-scan BBM data.

3. Further enhancement of import options: ThinProcess® (Zeiss) import is implemented.

4. COM interfaces enhancement:

- Multi-scan reverse engineering Python example is added

- Clear operation for Color target and Integral target added

- Computational functions called through COM update Design Builder panel settings

5. Catalog news:

- Catalog is extended with Schott Glass data

- Interface was improved: numbers columns removed, capabilities to sort and filter through small buttons in the column header are added.

6. The "New Project" option is now more friendly: it opens now several panels frequently used in the work flow.

7. Bugs fixing:

- If Gradual Evolution started from the empty design, in some cases it included a material, not selected in the corresponding setting. Fixed.

- If Specifications were loaded, a warning about wrong range was issued. Warning removed.

- In Import from Excel, measurement were not appended to the opened measurement table on the repeated clicks on Import buttons. Fixed.

24.32 (07.07.2024)

1. Further Enhancement of the Color Block:

- Lab color diagram is implemented (in Analysis/Synthesis and in Reverse Engineering).

- Color evaluation in Reverse Engineering added. Now it is possible to calculate colors of the current model and compare them with the colors of measurements and colors related to color targets.

- Display of colors in two different color spaces implemented. For example, it is possible to see color coordinates in numerical form in chromaticities and Lab spaces simultaneously.

- Complimentary target color characteristics are displayed better: "1 - " prefix added to indicate computed values.

- Saving the selected tabs in all color-related panels between OTF Studio sessions: When you save the project and close the program, the configuration of opened tabs is also saved. Upon reopening the same project, the tabs will be restored to their state at the time of closing.

2. Support of Multi-scan measurements in Reverse Engineering is implemented. Now it is possible to load measurements after each layer, apply Reverse Engineering models, and perform post-production characterization based on measurements recorded in-situ after deposition of each layer.

3. Electric Field display is improved: scaling of axes, better display of layer boundaries.

4. New Import feature: import from Optoplex files added.

5. The Reverse Engineering Model Builder is now more convenient: the selection of active layers for Random or Quasi Random errors is preserved throughout the entire reverse engineering process. This enhancement is particularly important for solving complex reverse engineering problems that require multiple steps.

6. Enhancement of COM interfaces: support of Multi-scan measurement implemented. New COM example demonstrating Multi-Scan measurement process (C#) added to the installation package.

7. Bug fixes:

- An inconsistency in "Reference" comb-box in the Differences panel of Color panel fixed.

- If Compare mode is active, checkboxes appeared on a new database panel, even if this database is not related to the items of the comparison. Fixed.

- Check boxes "Show Loaded Materials" and "Include index offset" placed on the top of the panel to avoid overlapping.

24.29

1. Further Enhancement of the Color Block: Calculations of color differences between Target and Design, Color Target and Design, and Target and Color Target.

2. Enhancement of the Color Block: display of target color characteristics. It works if the conventional target has compatible characteristics in the color-related spectral range.

3. Import from Semilab *.smdx files (ellipsometry) data implemented.

4. Configuration: Monitoring wavelength ranges added.

5. Added: Preventing sleep state of laptops when computations are running.

24.28

1. Enhancement of Color Block: specifications in colors are implemented. Color distances according to CIEDE 2000, CIE 94, CIE 76, CMC 1:1, CMC 2:1.

2. Enhancement of Color Block: Monte Carlo simulations of color coordinates are implemented.

3. Monte Carlo simulations of values are implemented.

4. Enhancement of Multi-Start algorithm: Jumps in Multi-Start Design Vicinity have 3 possible settings: Not Allowed (= No Jumps), Normal, Aggressive (fast jump to better design).

5. Reverse Layers added to the right-click menu of the Design Editor.

6. New Hotkey: Ctrl+Enter key combination works as "Commit" in all editors.

7. Improvement of DSG file import: correct processing of files with coinciding names of layer materials. To resolve collisions additional materials are renamed.

24.27

1. Monte-Carlo simulation of Electric Field is implemented.

2. New COM interfaces: Specifications and Specification Quality value are accessible with COM interfaces.

3. Compare Re(n) plots bug fixed: wrong display if "Show Loaded" is checked/unchecked.

4. Preview of Target and Specifications shows Expressions.