taReo Applications Offline

Possible applications of the software are much broader than just supporting and controlling the processes of depositing multilayer coatings. The program has a range of interesting offline applications that enable the creation of custom plugins.

Virtual Deposition Interface

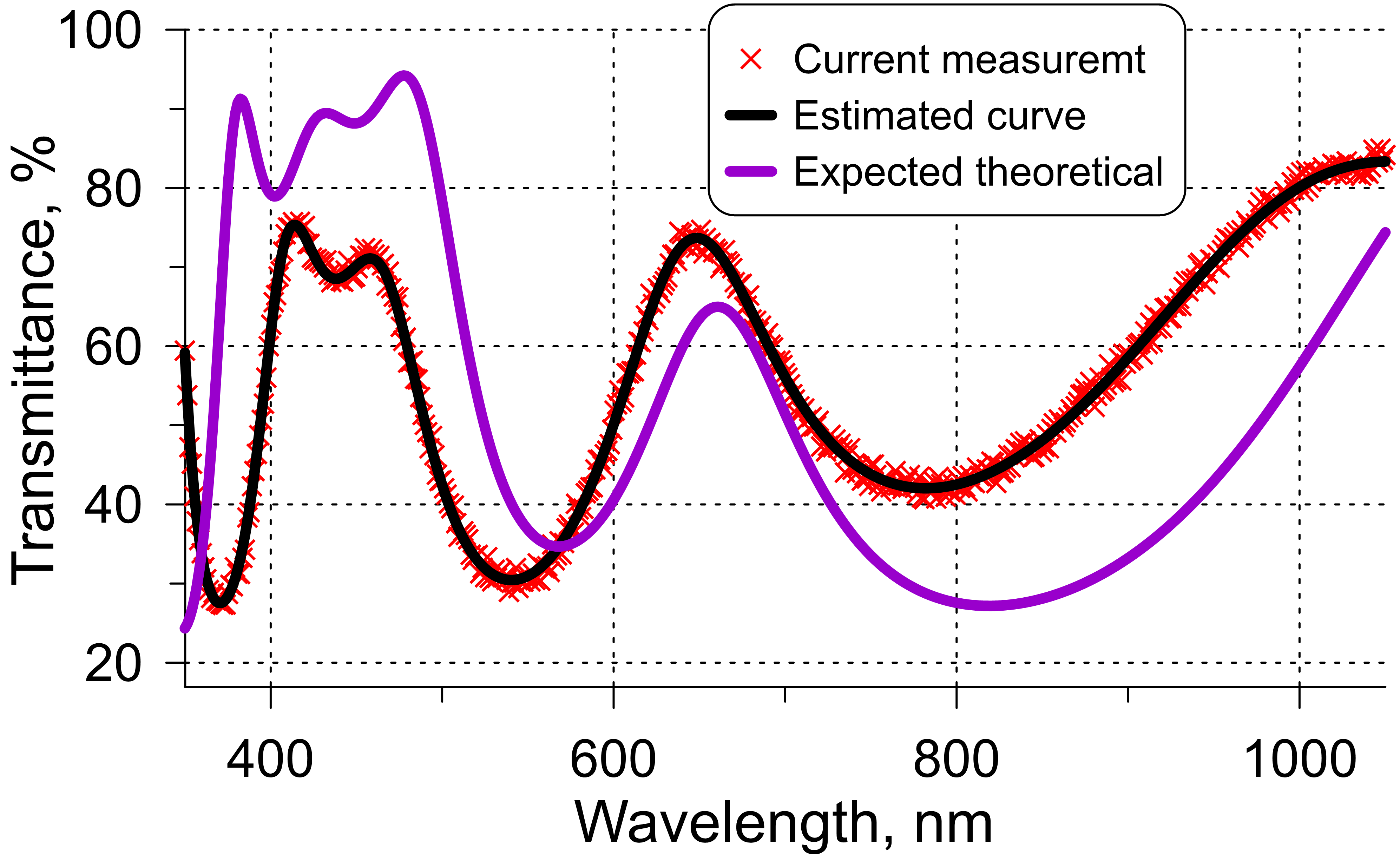

The Virtual Deposition Interface (VDI) provides you with the capability to conduct and manage virtual depositions, simulating real production runs. The Virtual Deposition Interface serves as a standalone interface that can be utilized within a separate program as well.

With VDI, you have the ability to simulate various deposition parameters according to your specific requirements. This includes manipulating optical constants of layer materials with predefined errors, controlling deposition rates and their fluctuations, adjusting shutter delays, and introducing noise to measurement data. Naturally, you can expand the range of simulated parameters to suit your needs.

taReo includes an example that emulates a deposition process controlled by broadband monitoring. This particular example represents the most advanced and demanding scenario, serving as an excellent starting point for developing your own simulator.

- By introducing additional elements such as noise, offsets in experimental data, and changing strategies involving test glasses and deposited layers, you can customize and enhance your simulator.

- To evaluate the production yield and identify critical layers for deposition, you can conduct 100-200 virtual deposition runs using your simulator. This approach provides a reliable estimation of the production yield and enables monitoring of the layers that have the greatest impact.

- Throughout these simulations, you can experiment with various reoptimization concepts. For instance, you can explore whether to reoptimize after each layer deposition or consider skipping reoptimization for certain layers. Additionally, you can investigate strategies such as inline correction of thin film optical constants to further refine your simulation process.

Analysis and design of multilayers

- The functions and algorithms of taReo offer versatile capabilities for the analysis, synthesis, and characterization of optical coatings. You can utilize these functions and algorithms as evaluation components to create tailored thin-film software that meets the specific industrial requirements of your company or addresses the challenges of your scientific research.

- For instance, you can use taReo to evaluate spectral characteristics such as reflectance, transmittance, back side reflectance, ellipsometric angles, and more, on any desired wavelength grid. Additionally, you can calculate various properties of the coatings, including color, integral values, averages, and other characteristics.

- With taReo, you have the flexibility to construct a unique thin-film software solution tailored to the specific needs of your company or scientific research, allowing for comprehensive analysis, synthesis, and characterization of optical coatings. In this context, taReo serves as a valuable auxiliary calculation tool.